Finest Heat exchanger Manufacturers in Nigeria | Shiraz Group

Shiraz Group is one of the Finest Heat exchanger Manufacturers in Nigeria, is renowned for its high-quality products. As trusted suppliers and exporters in Nigeria, we provide top-of-the-line heat exchangers designed to efficiently transfer heat between different substances, such as liquids or gases, without mixing them. These advanced systems are widely sought after across various industrial sectors due to their exceptional functionality. We continually integrate the latest technological innovations into our heat exchangers to boost their performance and reliability. Explore the various types, benefits, and applications of our heat exchangers to see how they can improve your processes!

Types of Heat Exchangers Manufacturer in nigeria We Offer

As a leading heat exchanger supplier and exporter in nigeria, we offer a wide range of heat exchanger types, including:

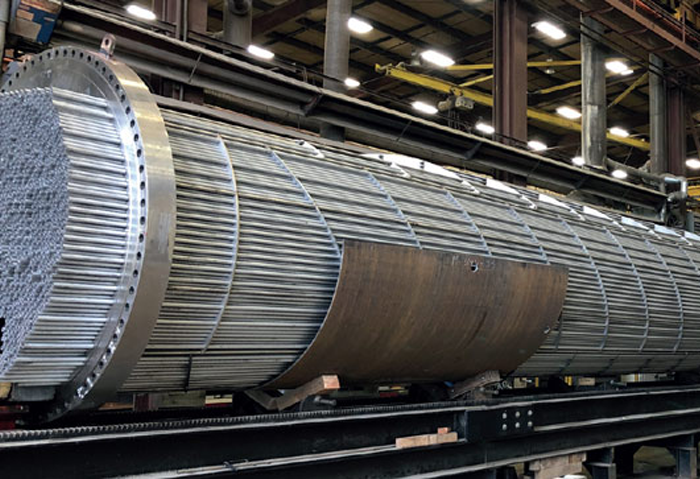

- Shell and Tube Heat Exchanger: : These are commonly used in power plants, refineries and HVAC systems due to their mechanism and new technologies such as helically corrugated tubes for increasing performance. The microgrooves and tabulators help for increasing heat transfer up to 20%.

- Plate Heat Exchanger: Our gasket-free plate heat exchangers offer increased performance and pressure ratings. Commonly used in refrigeration, HVAC, and food processing, they provide superior efficiency compared to storage systems.

- Air-Cooled Heat Exchangers: Ideal for industries with limited access to cooling water, such as petrochemical and refineries. Advanced designs and variable speed motors optimize energy use and maintain stable operating points, making them suitable for renewable energy plants.

- Double-Pipe Heat Exchangers: Featuring high-efficiency fans and a coiled design to minimize fluid turbulence, these exchangers are used in pharmaceutical and oil & gas industries. Their simple design facilitates cleaning and ensures high heat transfer rates.

Specifications of Our Heat Exchanger in nigeria

We have mentioned below a technical sheet for you reference:

| Parameter | Shell and Tube Heat Exchanger | Plate Heat Exchanger | Air Cooled Heat Exchanger | Double Pipe Heat Exchanger |

|---|---|---|---|---|

| Heat Transfer Rate | 1000–20,000 kW | 50–5000 kW | 10–2000 kW | 1–1000 kW |

| Heat Transfer Coefficient (U) | 300–1500 W/m²•K | 1500–5000 W/m²•K | 100–800 W/m²•K | 500–1500 W/m²•K |

| Flow Rate Range | 0.5–20 m³/hr | 1–500 m³/hr | 1–50 m³/hr | 0.1–5 m³/hr |

| Temperature Difference Range | 10–600°C | 1–100°C | 10–200°C | 10–200°C |

| Material Thermal Conductivity | Stainless Steel: ~16, Copper: ~400 | Stainless Steel: ~16 | Aluminum: ~237 | Carbon Steel: ~45 |

| Operating Pressure Range | Up to 100 bar | Up to 25 bar | Up to 20 bar | Up to 35 bar |

| Operating Temperature Range | -200°C to 800°C | -40°C to 180°C | -20°C to 400°C | -40°C to 300°C |

| Efficiency | 60–85% | 85–95% | 60–75% | 50–70% |

| Compactness (W/m³) | 100–500 W/m³ | 500–2000 W/m³ | 50–300 W/m³ | 100–800 W/m³ |

Heat Exchangers Features and Benefits:

As one of the leading heat exchanger manufacturers, suppliers and exporters in Nigeria, we have incorporated various advanced features into our heat exchangers, offering higher benefits, including:

| Feature | Benefit | Technological Update |

|---|---|---|

| Compact Design (Plate Heat Exchanger) | Our heat exchangers offer a space-saving design, ideal for small to medium-scale systems. | 3D-printed plates create a smaller form factor with improved heat transfer. |

| High Pressure Capability (Shell and Tube) | These heat exchangers can withstand high pressure, making them perfect for harsh industrial environments. | Advanced welding techniques and enhanced materials (e.g., titanium) enable use in extreme pressure systems. |

| Finned Tubes (Air Cooled Heat Exchanger) | Increased surface area for heat dissipation eliminates the need for water cooling. | Enhanced fan blade design and variable-speed motors optimize airflow efficiency. |

| Corrosion-Resistant Materials (All Types) | These heat exchangers offer a longer lifespan and reduced maintenance costs. | New high-performance coatings and corrosion-resistant alloys like Hastelloy and Inconel are used. |

| Modular Design (Plate Heat Exchanger) | Our heat exchangers provide greater flexibility for scaling up or down as process conditions change. | Gasket-free modular units simplify maintenance and reduce leakage risks. |

Applications and Uses of Our Heat Exchanger

As one of the top heat exchanger manufacturers & suppliers in Nigeria, all our models are equipped with the latest technological advancements and are widely used across various industries, including:

- HVAC Systems: Regulate building temperatures with efficient heat transfer between air and water.

- Power Plants: Improve efficiency and performance by recovering waste heat from exhaust gases.

- Refrigeration and Air Conditioning: Enable continuous cooling cycles by producing cool, condensed refrigerant gases.

- Chemical Processing: Maintain precise temperatures for reactions and distillation processes.

- Automotive Radiators: Prevent engine overheating by dissipating heat from engine coolant.

- Oil and Gas Industry: Facilitate heat transfer in refining and petrochemical processes.

- Food and Beverage Processing: Control heating and cooling stages for pasteurization and sterilization.

- Solar Water Heating: Transfer heat from solar-heated water to domestic water systems.

As one of the best heat exchanger manufacturers, suppliers, and exporters in Nigeria, we at Shiraz Group are providing the best quality heat exchangers that are used for transferring heat between various forms without mixing them. These heat exchangers are highly used in multiple industries due to their efficient mechanisms. We have also incorporated multiple technologies to improve performance. For more information, contact us today!